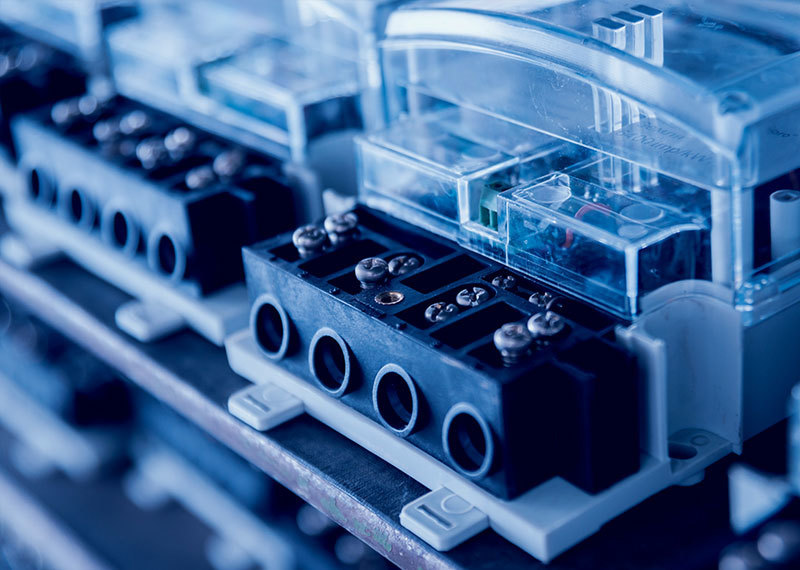

Lithium battery additive production line

Lithium battery electrolyte is also known as the blood of lithium batteries. Generally speaking, there are three types of lithium battery electrolytes: solid electrolytes, molten salt electrolytes, and liquid electrolytes.

Lithium battery additive production line

Lithium battery electrolyte is also known as the blood of lithium batteries. Generally speaking, there are three types of lithium battery electrolytes: solid electrolytes, molten salt electrolytes, and liquid electrolytes.

Lithium battery additive production line

Lithium battery electrolyte is also known as the blood of lithium batteries. Generally speaking, there are three types of lithium battery electrolytes: solid electrolytes, molten salt electrolytes, and liquid electrolytes.

Lithium battery recycling line

Lithium-ion batteries use lithium alloy metal oxides as the positive electrode material and graphite as the negative electrode material, using a non-aqueous electrolyte solution.

Lithium battery recycling line

Lithium-ion batteries use lithium alloy metal oxides as the positive electrode material and graphite as the negative electrode material, using a non-aqueous electrolyte solution.

Lithium battery recycling line

Lithium-ion batteries use lithium alloy metal oxides as the positive electrode material and graphite as the negative electrode material, using a non-aqueous electrolyte solution.

Lithium battery recycling line

Lithium-ion batteries use lithium alloy metal oxides as the positive electrode material and graphite as the negative electrode material, using a non-aqueous electrolyte solution.

Lithium battery recycling line

Lithium-ion batteries use lithium alloy metal oxides as the positive electrode material and graphite as the negative electrode material, using a non-aqueous electrolyte solution.

Lithium battery recycling line

Lithium-ion batteries use lithium alloy metal oxides as the positive electrode material and graphite as the negative electrode material, using a non-aqueous electrolyte solution.

Provide specific measures and technologies, combining aspects of equipment, processes, environmental protection, quality, and automation. Simultaneously, identify common problems and countermeasures to ensure the solution is comprehensive and practical.

This plan needs to be built step-by-step, but the content must be relevant to the food industry.

This plan needs to be constructed step by step, but the content must be relevant to the pharmaceutical industry.